- Nine Dot Connects

- Webinar of the Month

- Recently Posted Videos

- Altium Designer (70)

- Cabling & Wire Harness (5)

- Design for Manufacturing (10)

- Fabrication & Assembly (9)

- ECAD & MCAD (7)

- High Speed Design (20)

- Library Management (18)

- Vault & Data Management (16)

- PCB Broadview (4)

- PCB Elements (16)

- Power Supplies (5)

- Simulation (12)

One Size Fits All?

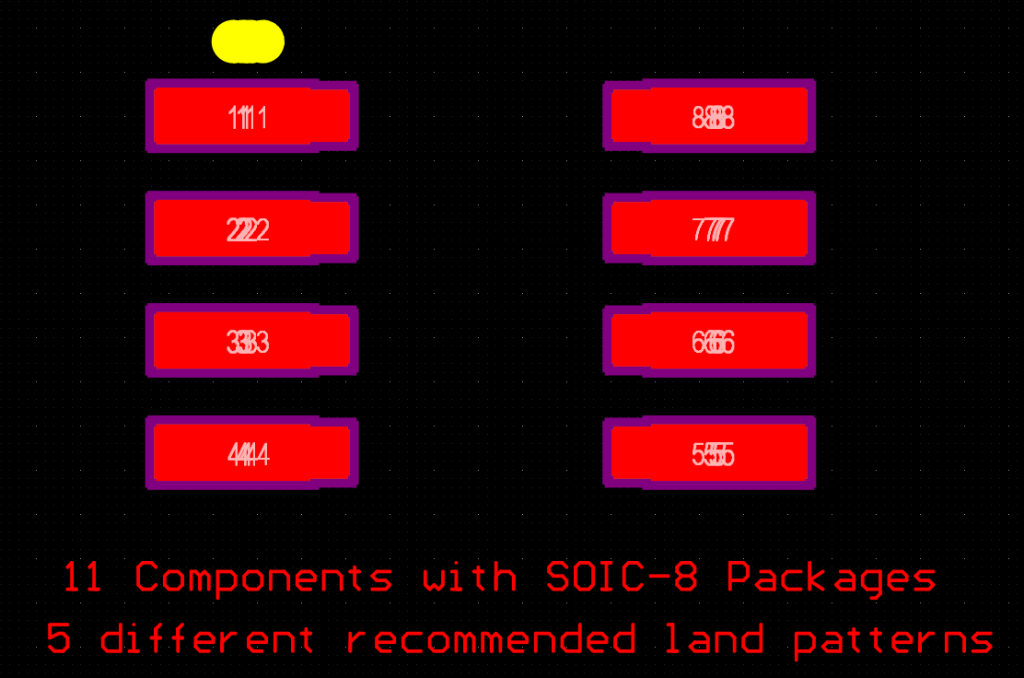

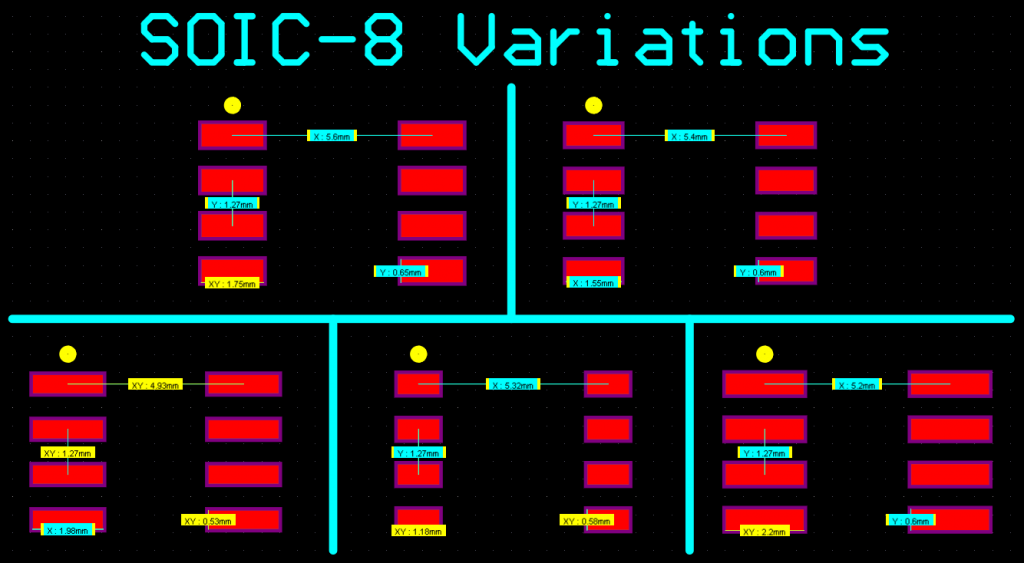

Actively involved in the business of restoring component libraries, we came across an interesting issue regarding the reuse of footprints. One benefit of standard package types is that it allows us to reuse footprints. There are standards by JEDEC and IPC that are carefully followed, right?

In our quest to understand what specs call the shots, we realized this goes way beyond industry specifications. The results were eye-opening for us, and we want to share our findings with you.

In this webinar:

- Briefly define the purpose of JEDEC and IPC and why it matters in our footprints

- Discuss the evolution of the specifications that drive the footprint dimensioning

- Look at various angles of approach when creating or reusing footprints

This video discusses why blind faith in IPC standards, manufacturing datasheets, and standard footprint types is not advised. Unfortunately, this puts a lot of people in a "damned if you do, damned if you don't" situation. If footprints are of great concern, one recommendation is to draw the footprint based on the component itself. This could be done either through 3D rendering, which should be based on the maximum material, or by measuring the physical component itself. This is what is used at the assembly plant JLCPCB. Robert Feranec has a video that shows this process. Granted, this would be for a huge company or a company concerned about reliability, but similar concepts can be employed at smaller companies.

Download Slides

Learn More