Electromechanical Consideration Example

The following is an example of an electromechanical concern and possible plan of action brought to a customer's attention for a high-power design. At Nine Dot Connects, we proactively assist our customers in design reviews and design creation. In this situation, not only did we flag the concern, we will implement it per the customer's review and response.

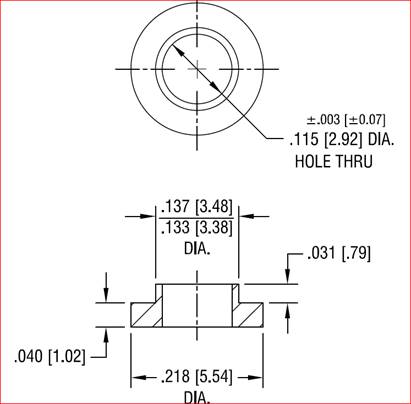

The TO-220 power transistors are in close thermal connection to the metal baseplate but electrically isolated from it. This is because they have to be at quite different voltages. This is typically handled by isolation hardware such as the Keystone 4724 used herein. At the core of this is a shoulder washer (in this case, Keystone 3049), which centers the screw (in this case 4-40 with a max major diameter of 0.112") such that it does not touch the inside of the hole.

This historically works fine for voltages up through a few hundred volts. Plates may be up to 1/8" thick. However, we're pushing it by running voltages up to almost 400V. Further, the plate is 1/2" thick, which brings up the question of how co-linear, concentric and straight are both the hole and the screw over this entire length. Thus several things might be worth implementing upfront.

- The hole diameter must be slightly larger than 0.137" on the cooling plate's outside (tube side).

- It would be best if the hole were bored-out to maybe 0.150"-0.160" through all but the last 0.025" to give more air clearance around the screw.

- A calculated-length piece of insulating tubing could be placed over each screw after it is inserted through the TO-220, standoff, and PCB, to provide positive assurance of insulation and physical spacing. (The length would need to be appropriate not to interfere. It could be heat shrinkable.) The diameter in 2) above could be chosen for optimal fit and assembly.

- Another option would be to press nonconductive inserts into the aluminum plate at these locations and then drill them out the desired hole in the middle of the insert to about 0.137". I do not know if such things exist, and this seems like more work.

- Remember, the thermal transfer is not via this screw: via the close coplanar flat surfaces on the IC body (TO-220) and the aluminum plate, separated by a thin layer of mica (or SilPad).