Simulation for Design (SfD)

Full board-level simulations have long been considered limited to the realm of very high-end or high-speed systems due to the cost of the software and the complexity of setting up, executing, and analyzing the simulation.

Through our "Simulation for Design" service, or SfD for short, we can address your concerns about cost and complexity with affordable solutions and comprehensive simulation and analysis. SfD is intended to provide simulation services throughout the entire design process, not just after the board layout.

There are many benefits to be gained from doing board-level simulations of your design before going to fabrication. It is even more beneficial if you perform these simulations during the schematic design and layout processes. If done properly, simulations can be used before the board's layout has begun. This "pre-layout" simulation can help locate potential flaws in the design before time and money are wasted on doing a layout that will need to be changed. Finding such issues at the end of the layout process can easily add two weeks to the schedule as traces and polygon pours must be stripped and rerouted.

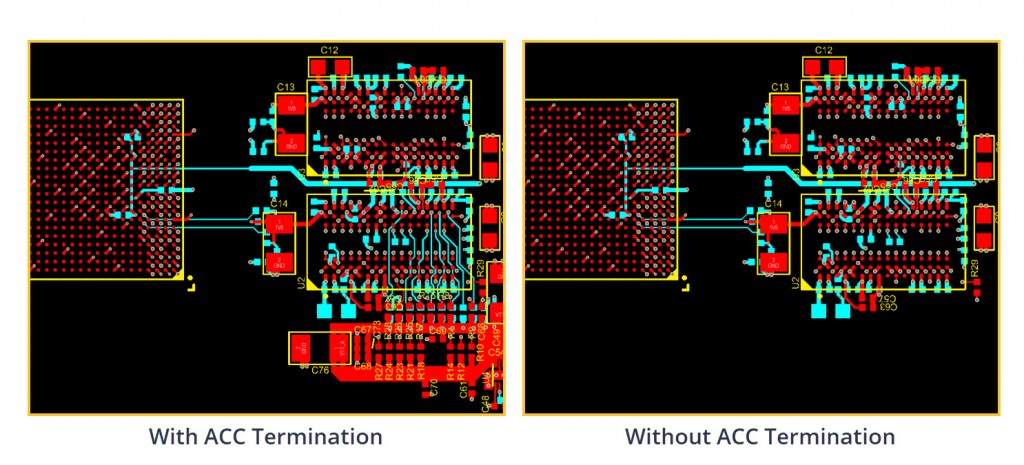

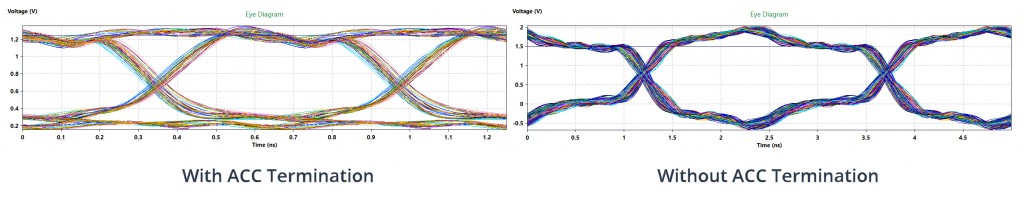

Note: ACC stands for Address, Command, and Control

The same time and cost savings apply if the simulation is used during the layout process. Considering the industry trend towards smaller boards, more parts, tighter routing, and shorter development cycles, finding a problem early in the process can greatly impact the project cost and delivery schedule. As shown in this example, based on simulation analysis, one can potentially remove a bank of terminators and still meet the necessary DDR3 speed and signal integrity requirements.

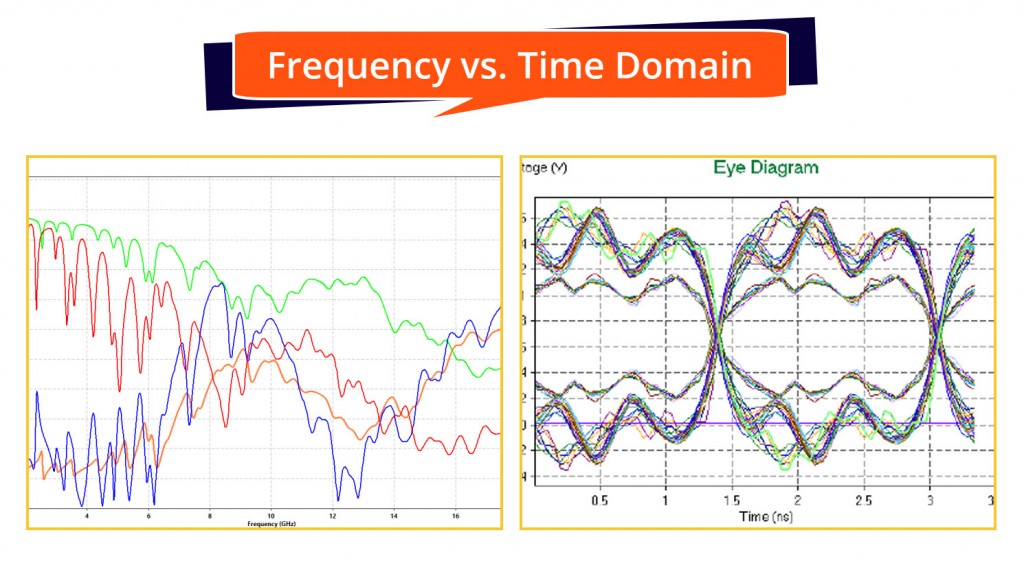

We conducted a 4-part webinar series on Practical Signal Integrity (SI). This series will provide much-needed answers on the five Ws (who, what, when, where, and why) and the 'how' of signal integrity and simulation.

Watch SI Videos

The SfD Workflow

Simulation is more than set up, execution, and analysis on an existing design. Though this tends to be the flow when simulation and design are treated as separate functions, the design is best served when the simulation is interwoven into the design process.

Upon Completion of Schematic Capture:

- Engineering performs the initial design and submits it for SfD pre-layout analysis.

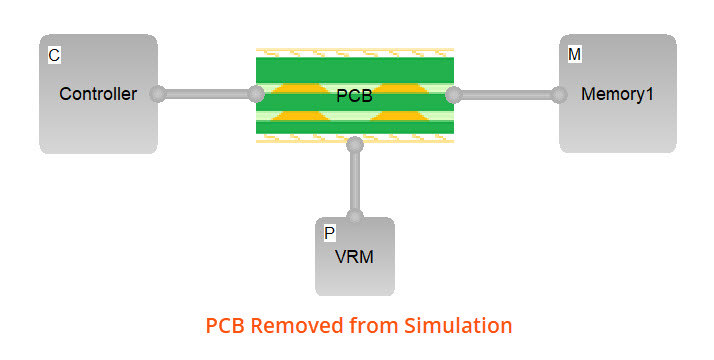

- SfD performs the initial setup, collecting all necessary SPICE and IBIS models and configuring the simulation files.

- SfD performs a pre-layout simulation, possibly providing Engineering with early warnings of potential design flaws such as improper transmission parameters, unrealistic timing expectations, and the need for or removing termination.

- The desired simulations are performed on the design, and the results are returned to the layout designer and/or engineer. Data from the simulation drives the creation of design rules to guide the placement of components and the traces' routing.

During the PCB Layout:

- Layout (and possibly engineering) incorporates any changes needed and submits to SfD.

- These steps are repeated as often as required until the design's critical sections meet the timing and signal integrity design parameters.

Completion of the PCB Layout:

- Final reports, including JEDEC Compliance, can be generated for design sign-off.

Benefits of SfD

When adding another process to the design flow, there is a cost associated with it. Ultimately, the intention and benefit of SfD are to ensure that the return of investment (ROI) is greater than the cost. Let's consider some of the benefits of SfD:

1. Determines potential signal integrity problems early in the schematic design and layout schedule when making changes has a much lower impact on the cost and schedule. For example, finding issues after the board has been routed can immediately add two weeks to the schedule.

2. Allows the use of "what-if" design and layout techniques. Potential benefits:

- Simplifying trade-offs in layout (e.g., having some traces closer together than would be acceptable by following "best practices" but which would simplify the overall layout)

- Simplifying routing in a crowded design, possibly even make-or-break the entire design

- Determining if it is acceptable to use "prohibited" layout paradigms such as crossing split planes

- Determining the need for additional return-current vias

- Determining the need for reference-plane coupling capacitors, etc.

Try Before You Buy

Should you be thinking about purchasing simulation software but are worried about knowing if the expense in both time and money will be worth it, we can help. We can perform a preliminary design review using our SfD process to give you a real-world demonstration of the direct benefits to your schedule and budget. Then when you're ready to purchase the software, you will already have applicable examples. Additionally, we can provide coaching as needed to get you up to speed quickly and efficiently.